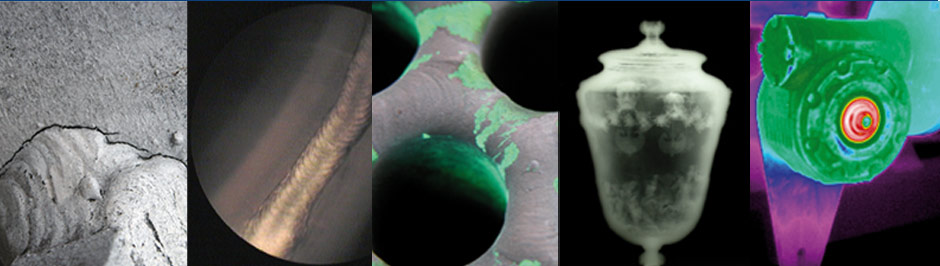

The Non destructive testing are a series of diagnostic methods able to determine faults in materials, machine components, welded structures, and projects during study or test phases, etc.;

Non destructive testing are defined as such inasmuch as they permit assessing the faults or structural characteristics of materials without altering their physical state or geometry.

The various methods used in non destructive testing are often complementary. Consequently, in order to choose test procedures, various factors have to be considered:

- PHYSICAL PROPERTIES: Ferromagnetism, electric conductivity, sound conductivity, X-ray opacity, material porosity.

- STATE OF MATERIAL: Rolled, forged, welded, extruded, etc.

- FAULT FINDING: Type, position, entity, etc.

- GEOMETRY: Shape and dimensions, degree of surface finish, etc.

STC performs non-destructive tests in company facilities or in its own laboratory.